What We Offer

Since founded in 1945, we’ve gained extensive experience in the fabrication of structural and miscellaneous steel for industrial projects

Fabrication

With years of experience and proper machinery, we have developed our process of converting steel into structures by processes including cutting, bending, and welding.

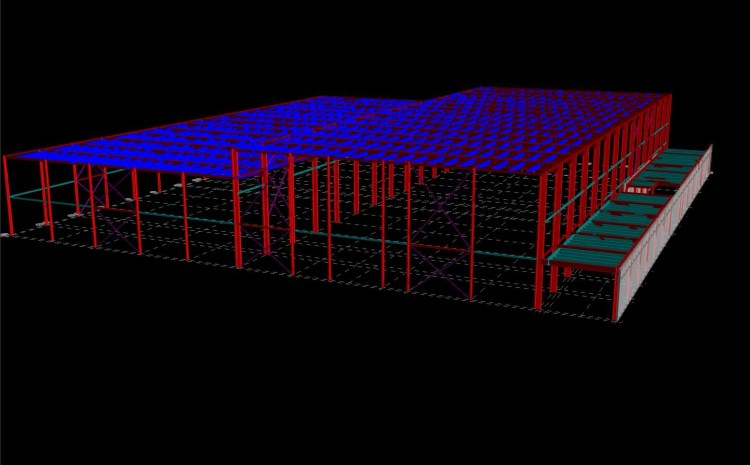

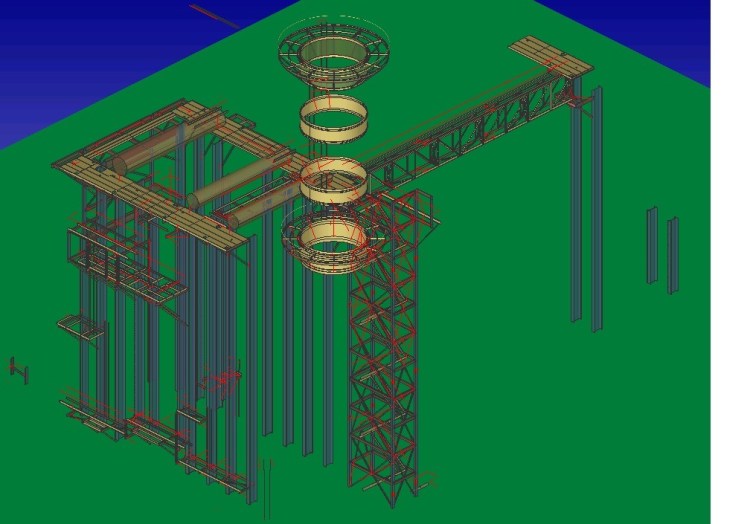

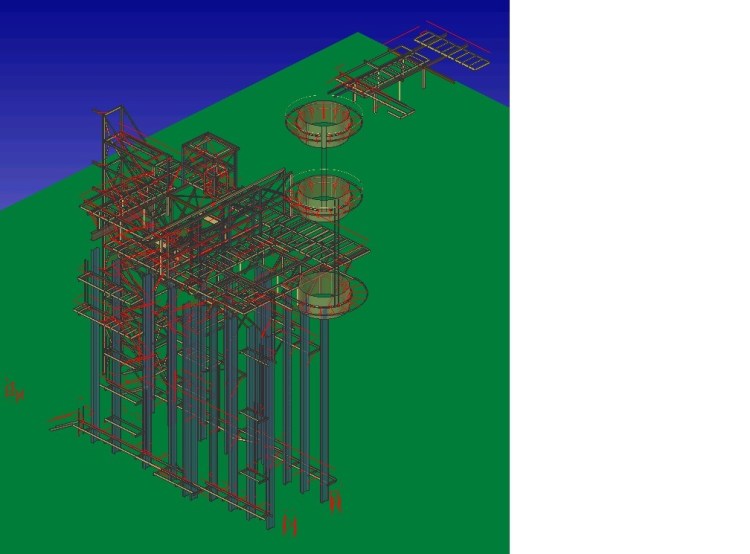

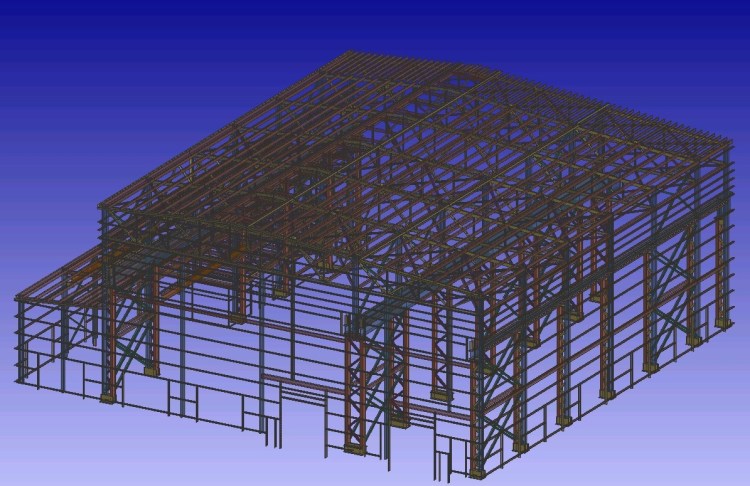

Engineering/Design

By vertically integrating and bringing engineering capabilities in house, we are able to design and engineer structures quickly and efficiently in order to meet project schedule demands.

Detailing

Interpreting architectural and structural engineering drawings to gain thorough knowledge of specific design or intent of the building or structure.

Quality Certifications

- American Institute of Steel Construction Building Fabricator Certification

- Canadian Welding Bureau Certification of Companies for Fusion Welding of Steel CSA Standard W47.1 in Division 2

- Shop Inspectors certified in accordance with The American Society of Nondestructive Testing per SNT-TC-1A.

- Certified Welding Inspector on staff.

- City of Los Angeles Department of Building Certification.

Efficient Delivery

Operating our own drivers with approximately 40 flatbed trailers throughout the regional area to ensure a timely and safe delivery to the jobsite. Additionally, we have partnerships with outside carriers for over the road shipment throughout the United States.

Fabrication Technology/Automation

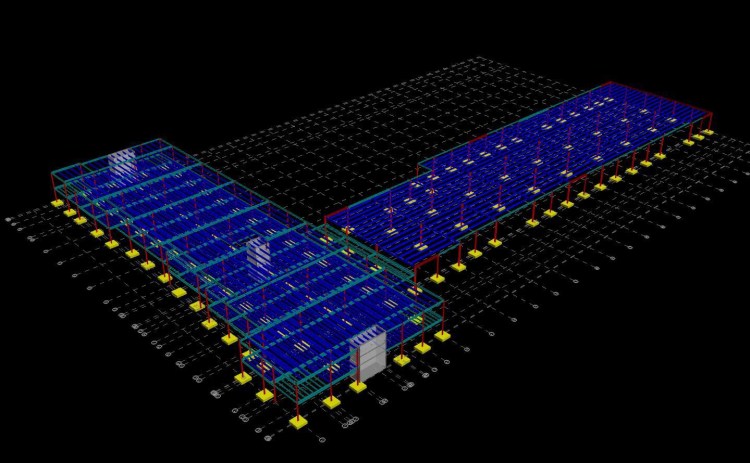

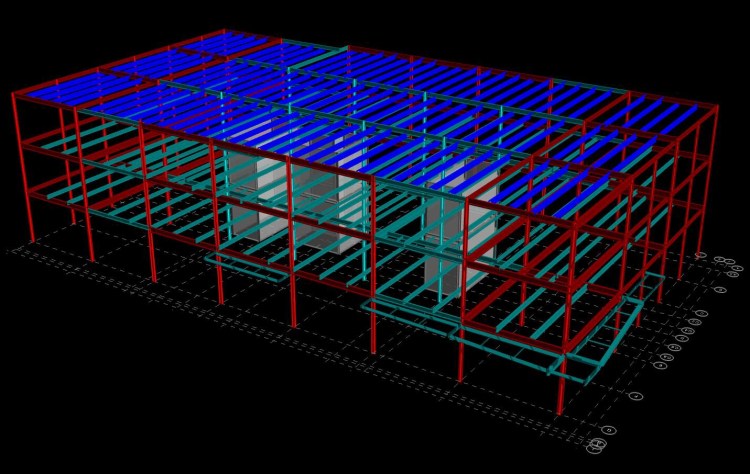

Once a project is awarded to The Arthur Louis Steel Company, the fabrication process begins with the assignment of each project to our Detailing/Engineering department. Our detailers use one of the following programs to generate the detailed fabrication and erection drawings for our projects.

- Advanced Steel

- RAM structural

- SDS/2

- TEKLA

- AUTOCAD

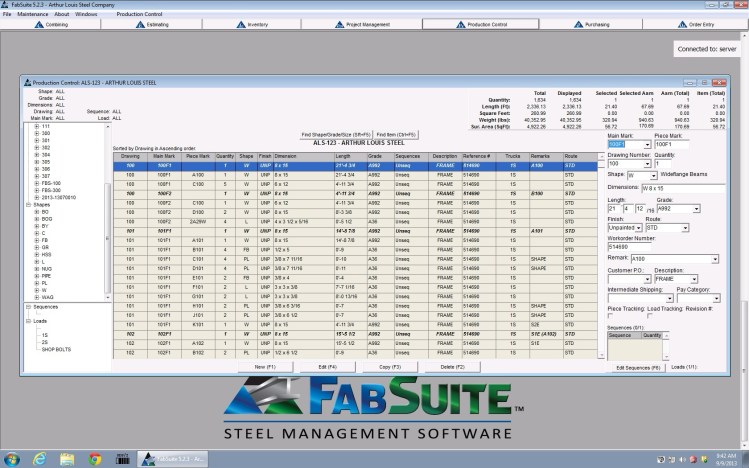

Following the receipt of files from detailing personnel they are imported into our steel fabrication management software, TEKLA. After importing the files into TEKLA, we are able to manage all aspects of each individual project such as:

- Submit drawings for customer approval

- Multing and nesting materials for procurement purposes

- Generate work orders for distribution to the shop floor to begin production

- Generate and manage all purchase orders related to each project

- Manage and document all drawing revisions

- Manage and document any project related change orders

- View real-time production statues, along with overall project completion benchmarks

- Complete project management activities, such as scheduling

- Record all QA/QC transactions for main and accessory steel members

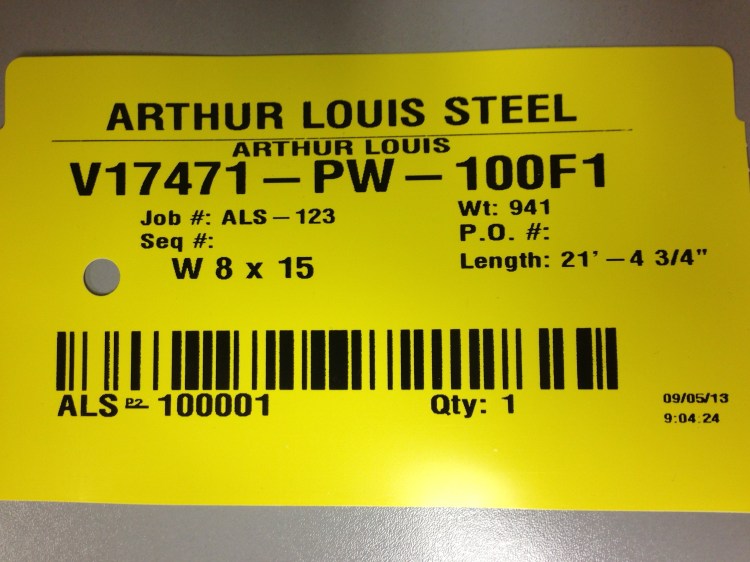

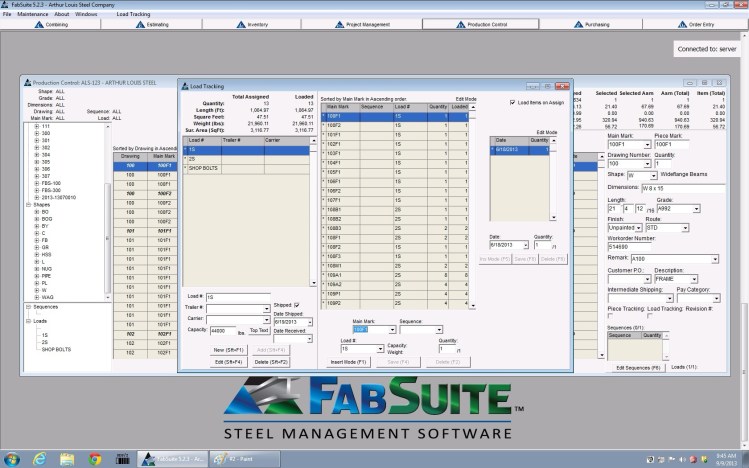

After each project has been through the work order generation process, the next step is to link it with our bar coding steel tracking software from P2 Programs STS (Steel Tracking System). Once the information has been linked to STS we have the capability to monitor every part fabricated through the various stages of the fabrication process. This is completed using mobile handheld PC’s that scan barcode tags as members travel throughout our facilities. Some of the tasks performed and electrically documented are as follows:

- Receive/Reject inbound raw materials

- Approve/Reject initial fit of main member assemblies

- Approve/Reject weld process

- Approve/Reject finals QA inspection

- Load trucks to coating contractors

- Receive material back from coating processes

- Create bundle lists for small parts being shipped on skids

- Load trucks to jobsite

Utilizing state of the art technology and automation allows The Arthur Louis Steel Company to reduce cycle time and compress project schedules. Work order generation, drawing control and production floor CNC equipment programming can now be completed in a matter of minutes while eliminating errors associated with manual data entry. The Arthur Louis Steel Company is extremely proactive when investigating and implementing new software and investing in new equipment. Our philosophy is to embrace the latest available technology in order for us to improve quality, project cycle times, and reduce internal costs. This philosophy has permitted us to improve our competitiveness in the global marketplace and become the supplier of choice for many of our customers.

Steel Project Management Software

RAM Engineering/Design Software Model

P2 Program Bar Code Tag